SCREEN PRINTING

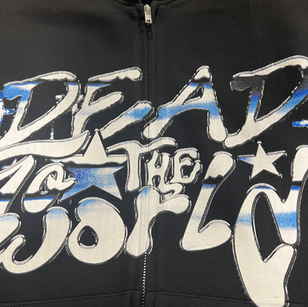

Screen printing is a precise technique that utilizes mesh screens to apply individual colors onto garments, creating vibrant, lasting designs.

Our advanced equipment allows us to print up to 8 colors on a single garment, and with simulated process printing, we can use halftones to replicate a wider color range. We also rely on the Pantone Color Matching System, ensuring your designs are printed with the utmost accuracy, so they reflect your artwork as closely as possible.

For larger print jobs, our jumbo screen setups can handle prints up to 17” wide by 21” tall, giving you the flexibility to bring bold, oversized designs to life.

Midnight Valley is not your typical print shop. We invest in top-tier equipment and materials, and we’re committed to going the extra mile to provide our clients with exceptional prints. When you partner with us, you can be confident that you're receiving products crafted with care and precision.

READY TO GET STARTED?

F.A.Q.

What is the typical turnaround time for an order?

Our standard production time is typically 10-20 business days. Production begins once the invoice is fully paid and all necessary blanks are in stock. Please note, additional services or customizations may extend the overall turnaround time. Rush orders are available, just specify when you need your product and we will get it you!

What is your minimum order quantity(MOQ)?

Our standard minimum order for screen printing is 24 pieces per design. For artwork with 7 or more colors, the MOQ increases to 50 pieces. For jumbo prints, the minimum order starts at 48 pieces.

Do you offer custom pantone color matching?

Yes, we use a solid coated Pantone guide for accurate color matching. In addition, our experienced graphic artists are skilled at selecting the right color palette for each order, combining both precise guidebook matching and their expertise in eyeing the perfect shade.

Do you offer samples?

Yes, we offer sample orders. While we don't typically offer screen printed samples due to the high upfront cost, we do provide DTF (Direct to Film) and DTG (Direct to Garment) options for standard sample orders. We highly recommend samples for more complex artwork or if you're particular about color accuracy. While we usually provide photo proofs for approval, for larger orders, we can rush a physical sample for final confirmation before production begins.